MPPT CONTROLLER

An MPPT (Maximum Power Point Tracking) wind and solar controller is an advanced device used in off-grid energy systems (off-grid systems) to maximize the energy yield of both wind turbines and solar panels and to charge batteries efficiently and safely.

What is MPPT?

"Maximum Power Point Tracking" (MPPT) means that the controller continuously searches for and tracks the maximum power point (MPP) of the energy source (solar panel or wind turbine).

For solar panels: The performance of a solar panel depends heavily on factors such as solar radiation, temperature, and shading. The MPP is the point at which the product of voltage (volts) and current (amperes) is greatest, thus generating maximum power. An MPPT controller dynamically adjusts the electrical load the solar panel receives to always operate at this optimal point. For wind turbines: Similar to solar panels, wind turbines have an optimal pivot point at each wind speed where they produce the most energy. An MPPT controller for wind turbines can adjust the turbine's speed to track this maximum power point, even at low wind speeds.

How does an MPPT wind and solar controller work?

Essentially, an MPPT controller is a DC-DC converter. It takes the irregular voltage and current from the solar panels and/or wind turbine and converts it into the optimal voltage and current needed to charge the batteries.

What makes MPPT special is?

Voltage conversion: When the voltage of the solar panels or wind turbine is higher than the battery voltage, the MPPT controller converts this excess voltage into additional charging current. This means that no energy above the battery voltage is "wasted."

Maximum power yield: By continuously monitoring the MPP, the controller ensures that as much energy as possible is harvested from the sources, even under changing conditions (e.g., cloud cover for solar, changing wind speeds for wind).

Advantages of an MPPT wind and solar controller:

Higher efficiency: Compared to conventional PWM (Pulse Width Modulation) charge controllers, MPPT controllers can increase energy yield by 10% to 30% or even more, especially in cooler temperatures or when there is a large voltage difference between the source and the battery.

Optimal battery charging:

They ensure precise, multi-stage charging of the batteries, extending their lifespan and preventing overcharging.

Flexibility in system planning:

MPPT controllers allow the use of solar modules with higher voltage than the battery voltage, which can simplify wiring and reduce costs.

Better performance in poor conditions:

Even under cloudy skies, partial shade, or low wind speeds, they still extract the maximum available power.

Hybrid use:

An MPPT controller designed for both wind and solar (often referred to as a "hybrid controller") allows the combination of both energy sources in one system, increasing reliability and autonomy.

In summary, an MPPT wind and solar controller is an intelligent "brain" in an off-grid system, ensuring that energy from wind and solar reaches the batteries as efficiently as possible to ensure a reliable power supply.

Oxide treatment of aluminum

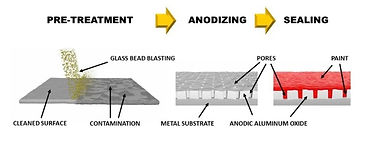

The "oxide treatment of aluminum" primarily refers to the process of anodizing (also known as anodizing). This is an electrochemical process that specifically strengthens and modifies the natural oxide layer on aluminum to give the material improved properties.

Aluminum naturally forms a thin, passivating oxide layer in air, which protects the underlying metal from further corrosion. However, this natural layer is very thin and not particularly resistant. Anodizing far exceeds this natural protective layer.

Properties and Benefits of Anodized Aluminum

The anodized layer imparts a variety of improved properties to aluminum:

Increased Corrosion Protection:

The oxide layer is chemically stable and effectively protects the underlying aluminum from most environmental influences, including salt water, acid rain, and many chemicals (in the pH range 5-8).

Increased surface hardness and wear resistance:

Anodized coatings are significantly harder than the base material, aluminum (hardnesses from 200 HV to 600 HV for hard anodizing). This significantly improves scratch and abrasion resistance.

Electrical insulation:

Aluminum oxide is an electrical insulator. Anodized aluminum parts are therefore not electrically conductive, which is an advantage in many applications. The dielectric strength depends on the coating thickness.

Temperature resistance:

Aluminum oxide is very temperature-resistant (up to 2000°C). However, the thermal resilience of anodized parts is limited by the melting point of the aluminum itself (approx. 660°C). Microcracks can occur at approximately 100-200°C, but do not significantly impair the protective effect.